Humo, Leche y Miel – (aka. they might be brainless)

Oddly, this series began as a way to understand beauty. What could I make if I applied my aesthetic processes to understanding how machines were made? Of course it was an absurd idea and yielded some absurd results…

The Series 2013-2015:

The Project: An outgrowth of beauty

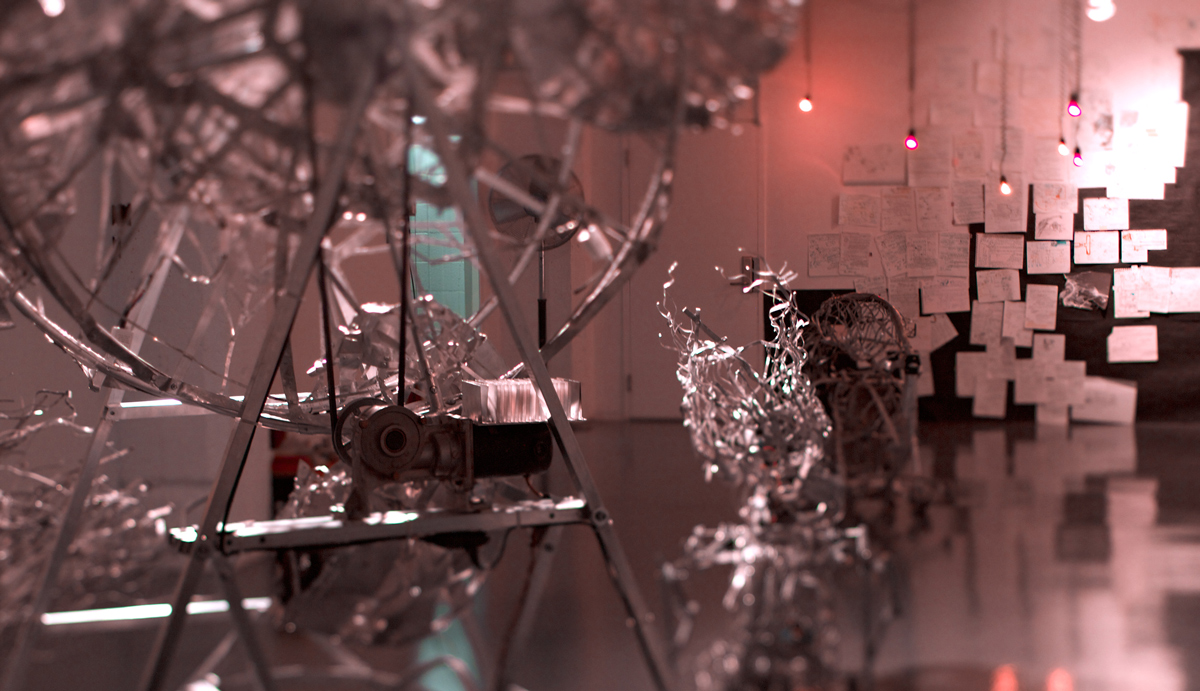

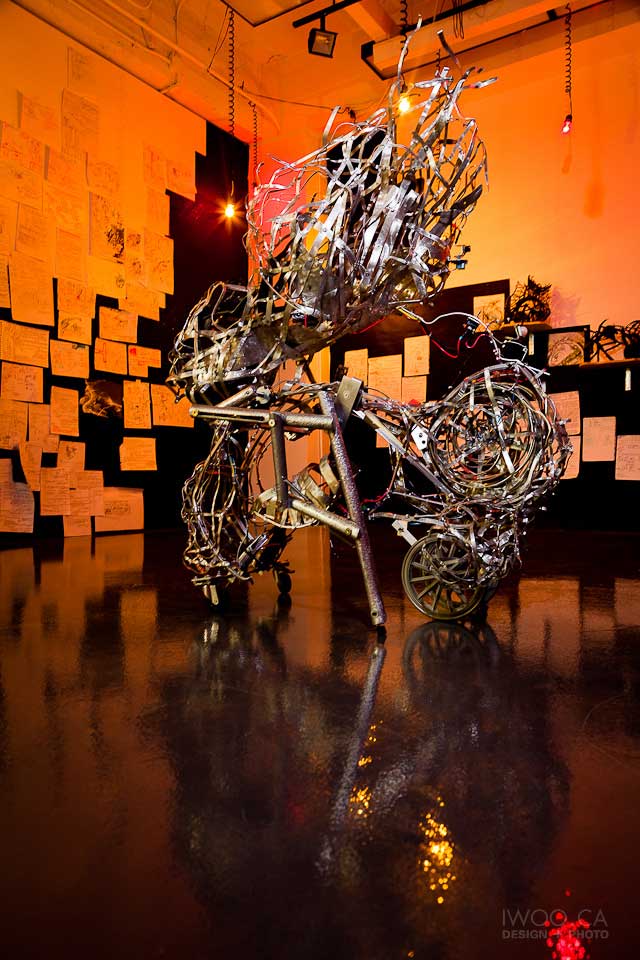

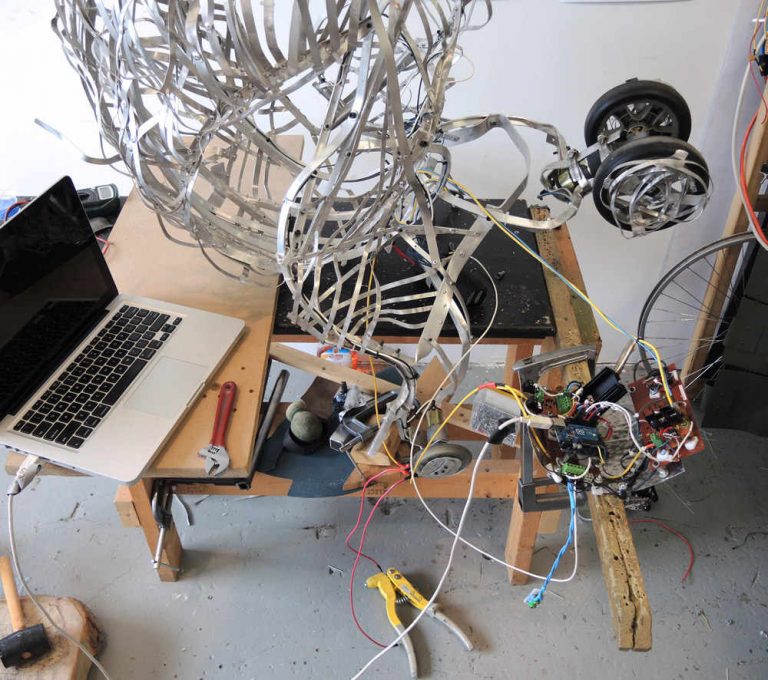

Humo, Leche y Miel (Smoke, Milk and Honey) began as my MFA thesis project. Originally 3 robots and a ferris wheel. The robots, (nick-named, “Walker,” “Porcupine”, and “Rocker”) ranged from four to five feet in height, three to five feet in length. The ferris wheel was ten feet tall.

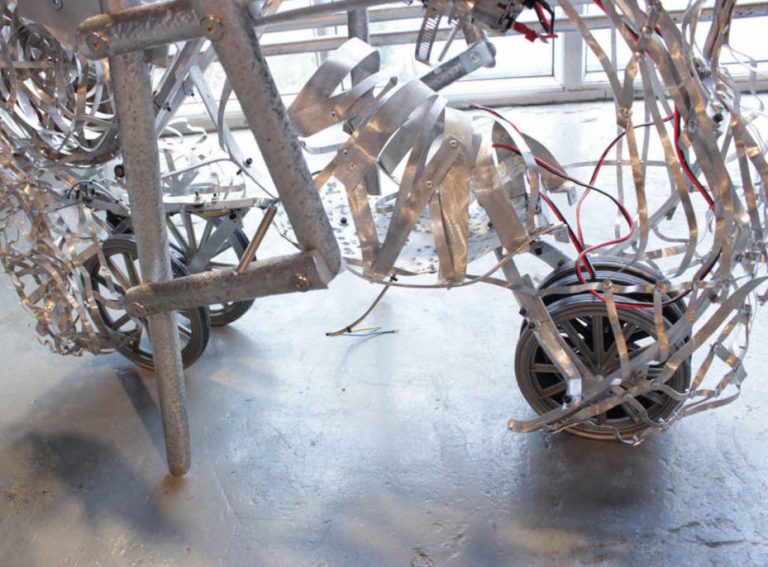

“Walker” and “Rocker” were propelled by legs, like the oars on a canoe. The “Blob” had purposely misshapen wheels. It never managed to roll its own weight, and was suspended from the ceiling.

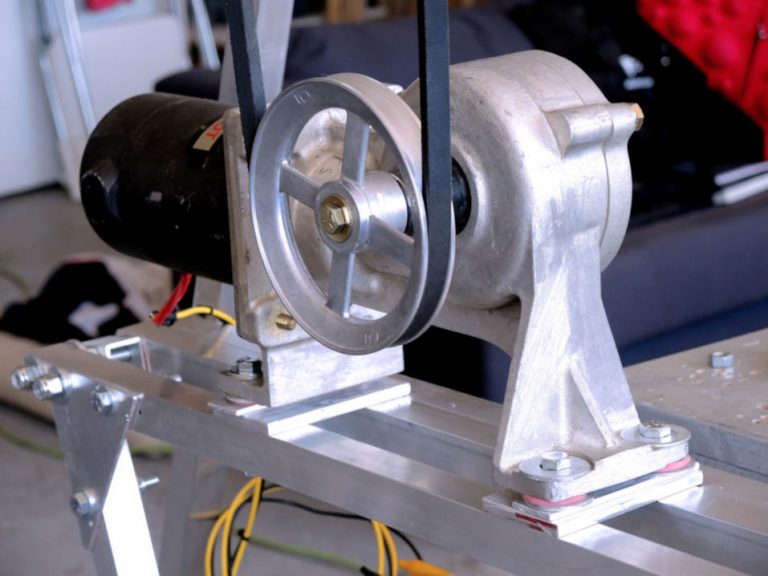

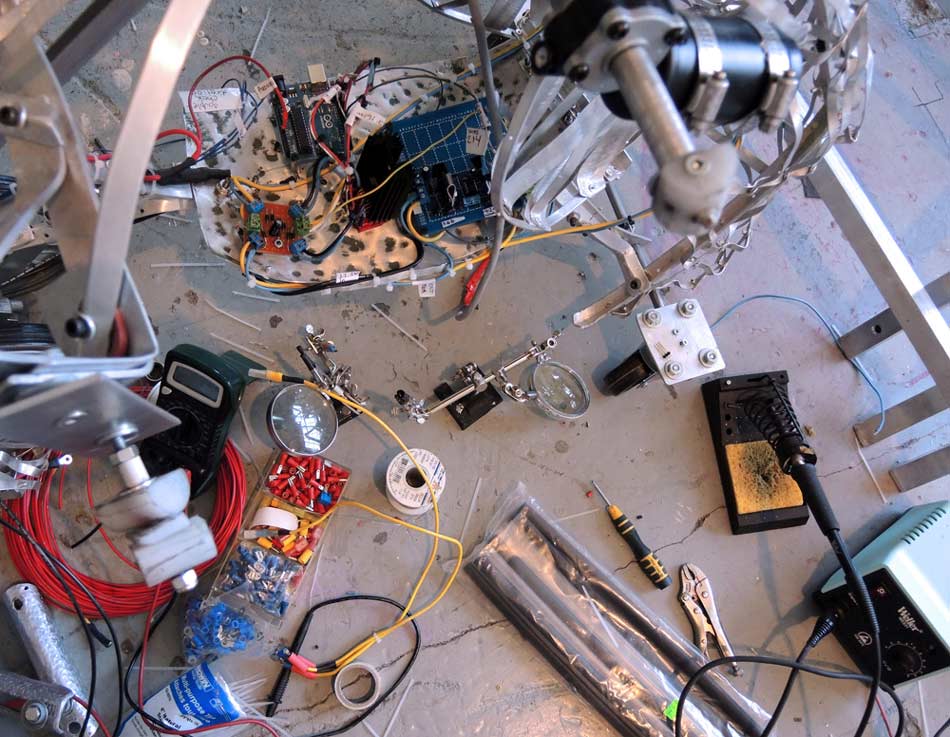

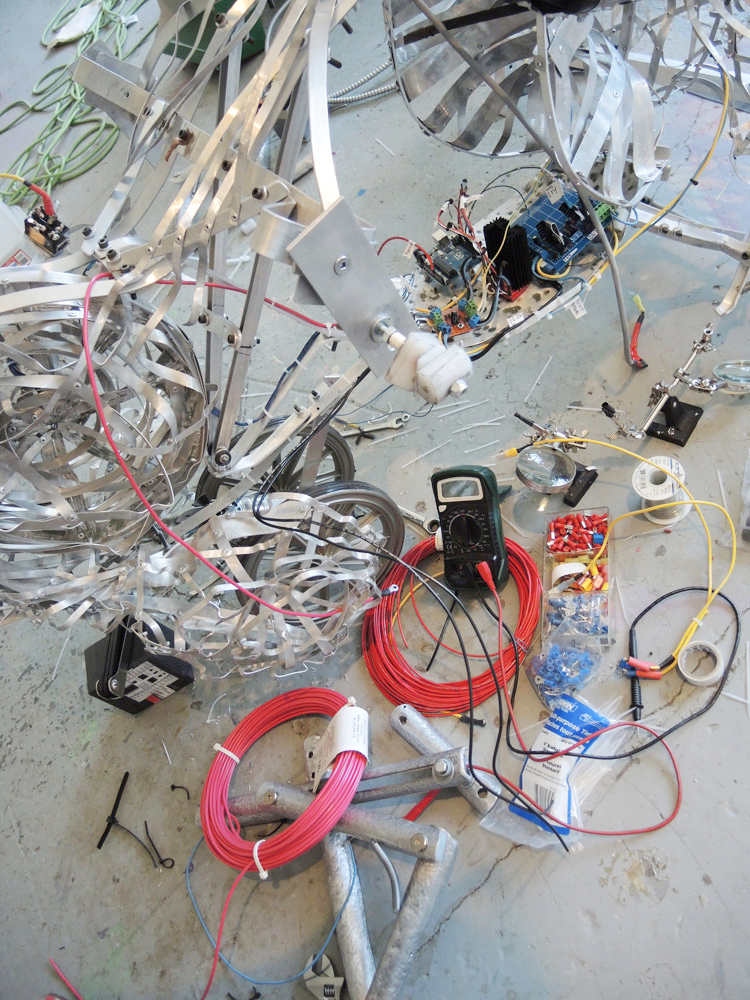

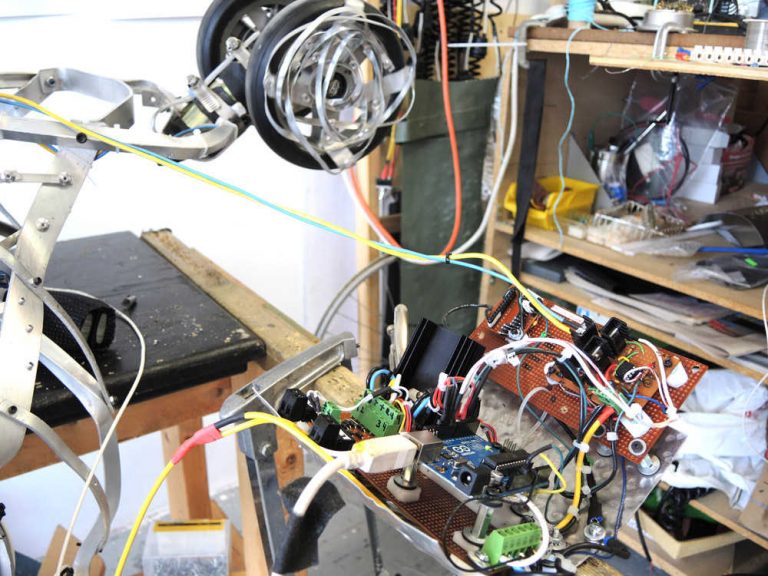

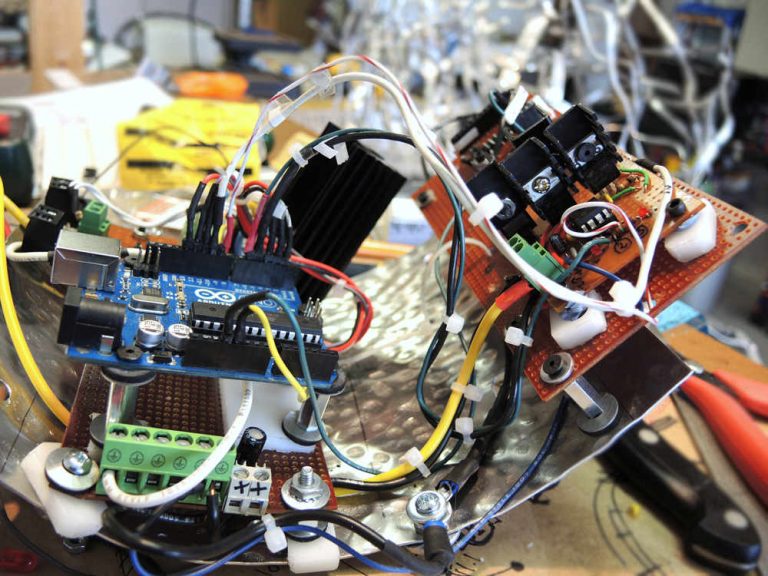

I built them to seem fluid, hermaphroditic, organic, but without hiding the clumsy mechanical and hand-made electronic elements. They were driven by various surplus gear motors and powered by rechargeable batteries.

I meticulously tracked my construction process, taking notes on every chip I incorporated, every motor driver, belt drive experiment, every sketch… I’d imagined presenting it so that anyone who was interested could use the data to create their own bots or construct their own stories… but it turned out to be too odd and circuitous, an information overload rather than an invitation. I’m not sure if it served a purpose to show all the processes…I should have posted it on Github.

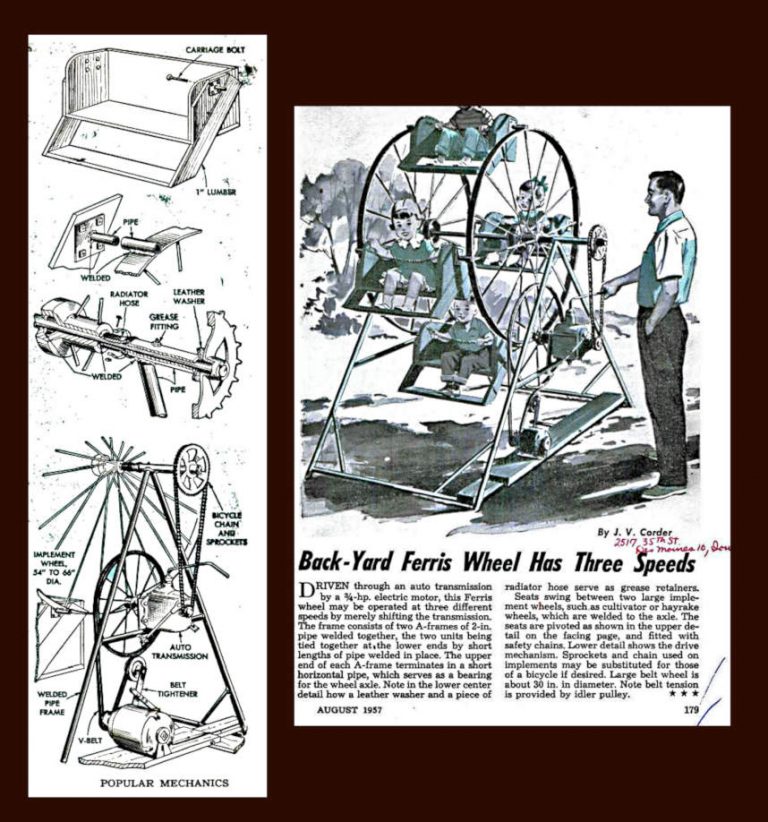

Ferris Wheel

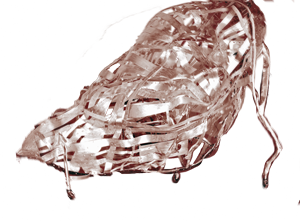

The ferris Wheel was another of those pieces that I began quickly and took months and months to finish. Originally part of the Humo, Leche, y Miel series, it was only exhibited once, at Daïmôn Artes Médiatiques in Gatineau at the end of 2015. The wheel turned very slowly. Instead of regular carriages, it had four aluminum forms that roughly resembled crustaceans or maggots. I spent a long time experimenting with sound, I wanted the wheel’s carriages to emit a combination of recorded audio loops mixed with surface transducers emitting the vibrations of the wheel’s turns and creaks. The audio was of my nephews screaming with glee. It didn’t work aesthetically. I love surface transducers but I’ve never managed to get anything other than high-pitched whines out of them… in the end the sounds of the wheel itself, the deep crick crack turning was enough on its own.

The maggots survived and are now perched on dead snags in the forest.

Walker and Porcupine,(Actual Robots)

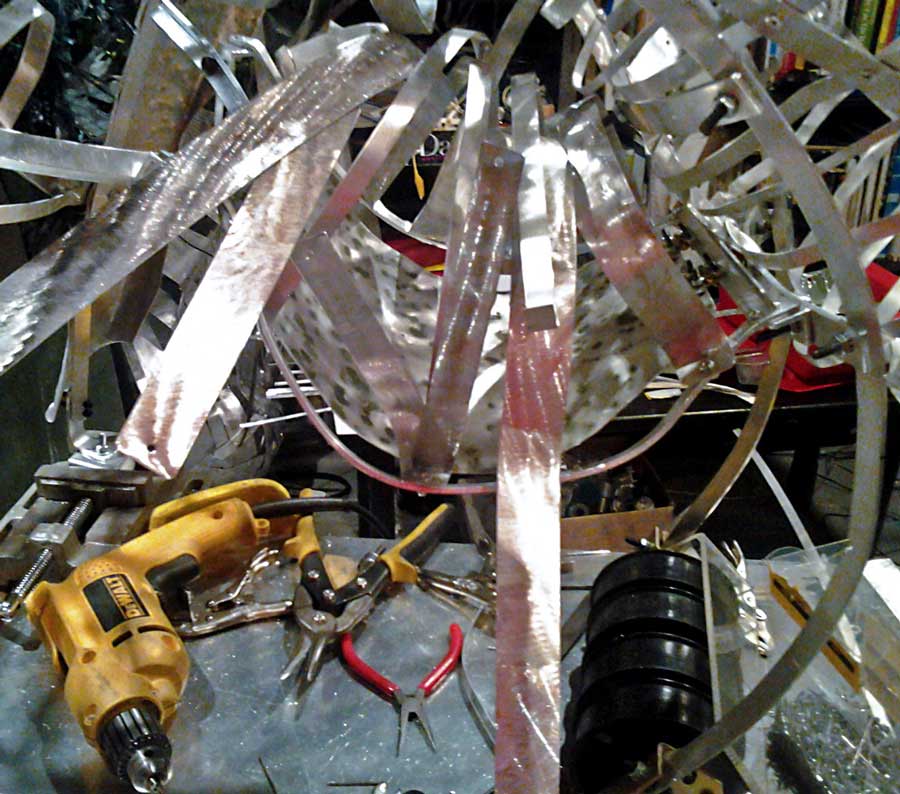

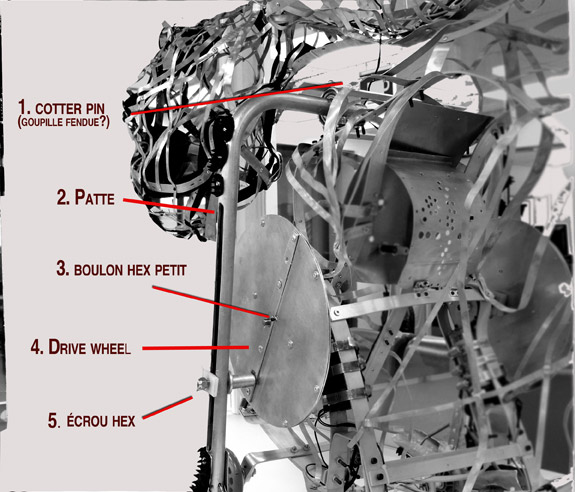

Porcupine: aluminum, paper, surplus motors (including vibrators), hardware, circuitry, sensors, software – 4′ tall x 2′ wide x 4′ long

Walker : aluminum, motors, vibrating motors, hardware, circuitry, sensors and software – 47”tall x 29” wide x 55” long

These were…actual robots… because they were autonomous, they had Arduino microcontrollers as the ‘brains’ controlling simple navigation using PIR’s, bump switches, and simple hobby-level Max Sonar sensors.

Basically this enabled them to tell: a) is there an obstacle? (sonar); b) did I just crash into something (bump switches); is the obstacle ahead, or the thing I just crashed into, a human or pet? (PIR’s). Their only response was to back up and change direction using random numbers to vary their movement enough so that they didn’t simply back up and repeatedly smash into the same object over and over again. Since you can’t really generate random numbers with an Arduino (at least back then,) I faked it by sticking a bare copper wire in one of the input pins.

Good times! But it all took too long. The abandoned kitten that wandered into the warehouse where I was living at the start of the project was a majestic 2 year old tabby ruling the back alley by the time I started testing the code inside the pieces. And by then I only had a tiny shared space, (~125 square feet, which sounds huge except I was building a ten-foot ferris wheel, 5 electronic sculptures and dozens of drawings at the same time,) with a narrow hallway to test them…

their movements were nowhere near as complex or robust as Rocker’s. Porcupine’s tips had tiny vibrating motors that caused it to shake and clack loudly.

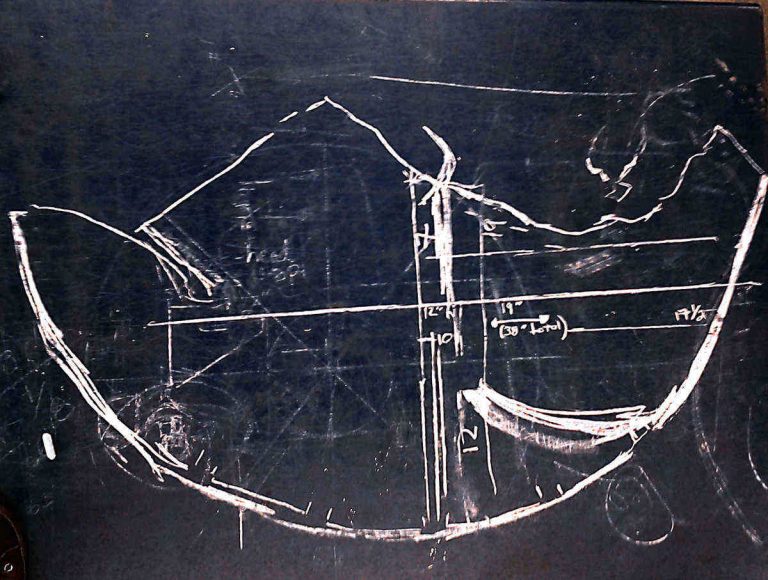

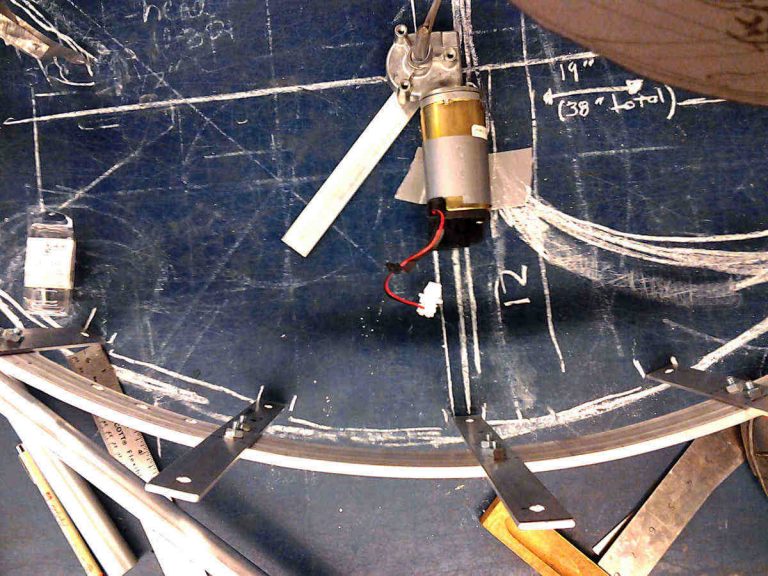

Blob

Blob

aluminum, rubber, hardware, batteries, motors – 5′ tall x 7′ long x 38” wide.

The problem, of course, is that I was building in the same way I was drawing, making a million preparatory sketches and detailed plans which I then mostly ignored. The problem is that when building a seven foot long metal blob with irregularly shaped wheels rolling, even over perfectly smooth ground, just trying things out over and over isn’t going to get you very far. It got me pretty far, but the wheels were not wheels, they functioned like canoe oars, tipping down and touching at intervals to create the jolting, jerking spasmic creature. This meant the rest of the blob needed to be perfectly balanced and self-supporting… somehow. I ran out of time and money before I could attempt two additional tests: 1) a separate base on shock absorbers, basically a dune-buggy 2) the bottom of the sculpture (facing the ground) lined with hundreds of springs with felt pads sewn on their tips. I still dream about springs…

The only time I exhibited the blob I suspended them to the ceiling on a chain so their kidney-shaped wheels only touched the ground at irregular intervals. Very unsatisfying.

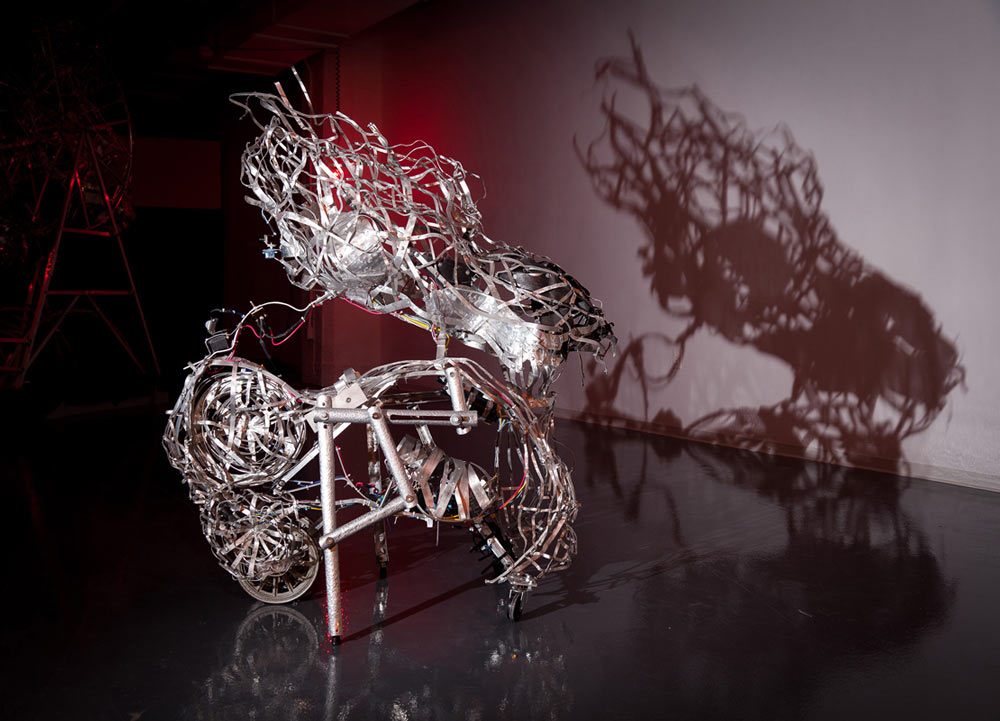

Rocker

Rocker

“Rocker” was my favorite, probably because they felt like I discovered them, rather than created them. It moved in an unpredictable arc, navigating blindly, working itself in and out of corners. I had them running one day during a gallery installation just to test the battery life (liPo). Turning around I realized it was gone. I found it wedged between a wall a magazine rack down a hall. It worked itself loose but took the whole magazine rack with them.

Its complex behaviours were due to its shape and slight asymmetry, they didn’t contain sensors or microcontrollers of any kind. They literally rocked back and forth, eventually coming full circle. Its upper portion weighed less than 2lbs., super springy, so it had a tendency to bounce off targets instead of crashing.

I had the chance to install it in the vitrine of the tiny airport at les îles-de-la-Madeleine, right in front of the security desk. I’ve always loved the odd, tense, banal non-space of airports. I would love to have an opportunity to do something in those spaces again one day. It was also amazing to see the islands, and to get to meet the people that worked at le centre d’artistes AdMare, mostly as volunteers.

Construction – Rocker

There was a built-in flaw to this series: I built every square inch of the walking/rolling pieces out of aluminum, even the motor shafts, the cranks, the wheel mounts. Aluminum is super light, doesn’t rust, easy to machine and a joy to bend with heat torches and rivet together into any shape. But it is brittle. No ‘bounce-back’ like other alloys. It’s also tricky to weld for a beginner, I tried to teach myself to use a TIG welder and mostly failed, burning tip after tip. There was no protective gear for someone my size in the metal shop! I had to twist my hair into a strategic knot to keep the welder’s helmet in place, and could barely pick up objects with the giant gloves.

Rocker worked well, while it worked, but the aluminum around the shafts eventually buckled and the cheap surplus motors failed in the middle of an exhibition. I’m not sure I would build more robots or moving sculptures, I’ve serious doubts about the life-cycles and energy usage of digital systems, but if I do I would take the time to build all moving parts out of a different alloy, steel? I’ve been told that the honey-combed density of 3-D printed materials can work even as joints for moving parts that are under stress and friction. I’m not so sure! Especially not biodegradable polymers.

An outgrowth of beauty

I was raised by chemists. In my mother’s loving cosmology, reality was something quantifiable and elegant, only briefly laid bare within chemical reactions. On the other hand, I never met my paternal grandfather, but heard about his half-copied, half-invented machines. In an age when service departments would’ve been on a different continent, he re-built assembly lines and industrial equipment on the fly. After his death, Cacharro, our old dog, slept in the last bell-shaped husk of a forgotten machine that had manufactured buttons, and the chickens roosted in the remnants of his underground workshop in the lush back garden of Llo-Lleo, until one day it collapsed after an earthquake.

2.

This project began when I stumbled upon Hieronymus Bosch’s Ship of Fools2. I was still thinking of the galleries unfurling behind me: the rise of a different kind of collective community marked (artificially?) by the transition between galleries full of bleeding Jesuses and beheaded saints to massive oils of picnickers grinning at their children and eating herring; nordic festivals of plenty rife with symbols beyond me to decipher.

I’d spent hours as a teenager absorbed by Hieronymus Bosch, but this one had always been my favourite. It seemed simpler, smaller than the epic Garden of Delights. The sullen, fatuous, energy that played across the surface of the painting seemed both a subtler, and more mysteriously charged expression of folly than his more fantastical creations. I’d never seen the real thing before. I still felt an affinity with this supposedly dead image.

The fool is one of those universal archetypes along the unstable spectrum of good and evil. Appropriation being a contemporary manifestation of an older, devious, sometimes brutal transfer of cultural information. The virgin, as the defender of purity, perfection and orthodoxy would seem about as far from the figure of the fool as you could get. But in South America, the virgin, like the Candomble god Exu3, combines characteristics of order and disorder, chaos and perfection. Like the trickster, she has the power of a shifting dual nature. In many Northern Chilean churches, statues of the virgin conceal older goddesses. Her devil dancers of the Diabladas4 are rooted in older myths of deities like Tiw and Anchoncho, protectors of the ancient silver mines of the Bolivian altiplano.

In Catholic traditions the fool as denier of god transforms into the wise fool who satirizes and deflates the powerful to expose corruption, as in Chaucer’s tale of The Summoner and the trial of farts.5

The fool is not just a contradiction of disturbing energies held in tension – cunning, naïveté, ruthlessness, conceit, duplicitousness, honesty (in the way those with nothing to lose are honest) – to me the fool is also present in instability and absurdity, in unpredictable feedback loops, and unexpected blowback.

If you look over my projects you will notice no Art Historical leitmotifs – no ships, no fools. But they are always there…

- The ship of Fools, Hieronymus Bosch, painted 1490 – 1500. Flemish section of the Louvre Museum, Paris.

- Exu, Legba, Èşù, there’s many deities from African, Caribbean and Brazilian traditions of this name. I was thinking of the Brazilian trickster god ofchaos, cross-roads and divine messenger.

- Originating in Bolivia in pre-Colombian times. In La Tirana, a town in the Chilean desert (named after a native rebel who converted to Catholicism), troops of dancing devils come to the shrine of the Virgen del Carmen each year during her feast July 12 – 16 .

- Geoffrey Chaucer The Somnours Tale. Canterbury Tales. ed. Paul G. Ruggiers A facsimile and transcription of the Hengwrt and Ellesmere manuscripts. University of Oklahoma Press. 1979. p. 313 – 341.